1. Battery Industry

Lithium ion battery is a secondary battery system in which two different lithium embedded compounds which can be reversibly inserted and removed from lithium ions are used as the positive electrode and the negative electrode respectively. When charging, lithium ions are removed from the positive electrode and embedded into the negative electrode through the electrolyte and diaphragm. In a discharge, on the other hand, lithium ions detach from the negative electrode, pass through the electrolyte and diaphragm, and become embedded in the positive electrode. The anode of lithium ion battery is made by mixing anode active substance, binder and additive to make paste adhesive evenly smeated on both sides of copper foil, after drying and rolling.

2. Electronics Industry

Graphite is widely used in the electrical industry as electrode, brush, carbon rod, carbon tube, positive electrode of mercury rectifier, graphite gasket, telephone parts, television tube coating and so on. Graphite electrode is the most widely used in the smelting of various alloy steel, iron alloy, will use a large number of graphite electrode. The graphite used in the electrical industry, generally the particle size and grade requirements are particularly high.

3. Flame - Retardants

SUNGRAF’S Expandable Graphite is widely used in flame-retardanting industry.It is produced by the chemical treatment of quality flake graphite, expandable graphite achieves an increased volume when exposed to rapid, intense heating. The resultant material can be re-compressed into a flexible, tough, and heat- and chemical-resistant sheet with a high degree of cohesive integrity. Expandable graphite is also used as an active, char forming fire retardant in non-structural polymers and in coatings.

4. Friction Materilas

Natural Graphite and Synthetic graphite are suitable for all kinds of friction material production, friction material is used to manufacture mechanical equipment transmission and braking parts, friction material is rely on friction action to perform the braking and transmission function of component materials, friction material special graphite powder is a kind of preparation of friction material, is a graphite powder with lubrication and wear resistance, Friction material special graphite powder and resin, rubber, reinforced fiber composite processing, friction material is a composite material, friction material special graphite powder can play the role of wear resistance, high temperature resistance, heat conduction, lubrication and so on.

5. Lubricantion

Graphite is often used as lubricant in machinery industry. Lubricating oil often can not be used at high speed, high temperature, high pressure conditions, and graphite can be at a 200℃ to 2000℃ temperature and also at a high sliding speed (LOOM /s) without lubricating oil work. Many of the transport of corrosive medium some equipment, are generally widely used graphite materials made of piston rings, seals and bearings, they operate, do not need to add lubricating oil, graphite is also a good lubricant for many metal processing (wire drawing, tube pulling).

6. Metallurgical Industry

Graphite and other impurity materials can be used as carburizers in the steelmaking industry. Carburizing uses a wide range of carbonaceous materials, including ink, petroleum coke, metallurgical coke and natural graphite. In the world steel carburizer graphite is still one of the main uses of earthen graphite.Graphite and Graphitization Petroleum Coke can be used as carburizers in the steelmaking industry. Carburizing uses a wide range of carbonaceous materials, including ink, petroleum coke, metallurgical coke and natural graphite. In the world steel carburizer graphite is still one of the main uses of earthen graphite.

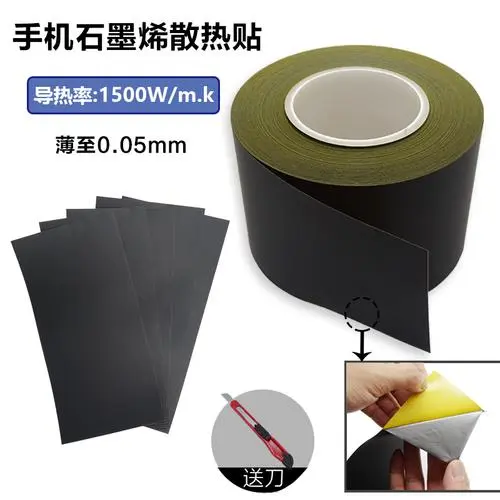

7. Mobile Industry

Thermal conductive graphite sheet is a new thermal conductive material, which conducts heat evenly in two directions, shielding heat source and components while improving the performance of consumer electronic products. The unique combination of thermal conductivity makes thermal graphite an outstanding material choice for thermal management solutions. Thermal conductive graphite sheet has ultra-high thermal conductivity in the range of 150-1500 W/ M-K in plane.

8. Refractory Materials

Magnesium-carbon brick is developed successfully as one of magnesium-carbon refractories in the middle of the 1960s, ; Magnesium-carbon bricks have been widely used in steelmaking so it has become a traditional use of graphite. Aluminum-carbon brick as aluminum-carbon refractory material is mainly used for continuous casting, a protective cover for flat steel billet self-positioning pipeline, underwater nozzle and oil well explosion barrel, etc.

Crucible made of graphite forming and fire-resistant cauldrons and related products, such as common crucible, curved neck bottle, plug and nozzle, they have high fire resistance, low thermal expansion, metal melting process, by metal infiltration and erosion is also stable, good thermal shock stability and excellent thermal conductivity at high temperature, So graphite and its related products are widely used in the process of direct melting metal.