High definition Graphite Electrode In Furnace - UHP Grades Graphite Electrodes – Sungraf Detail:

Products Details

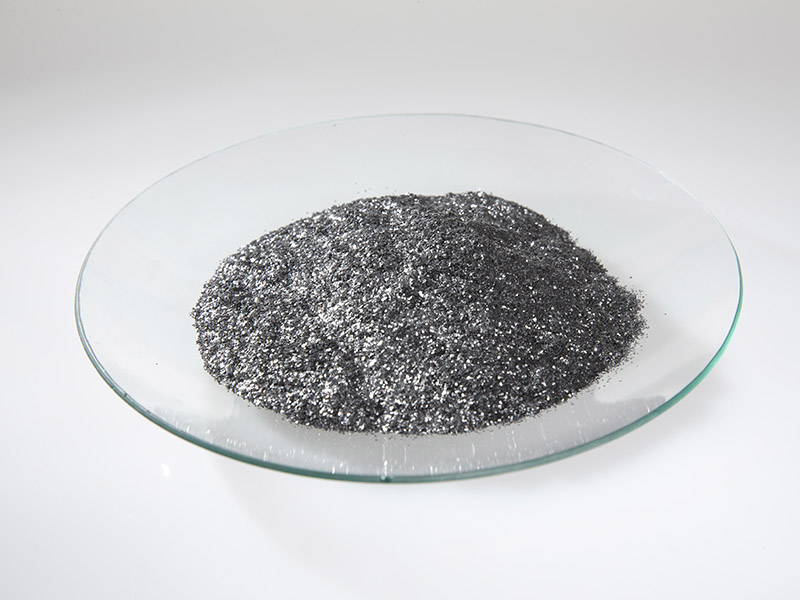

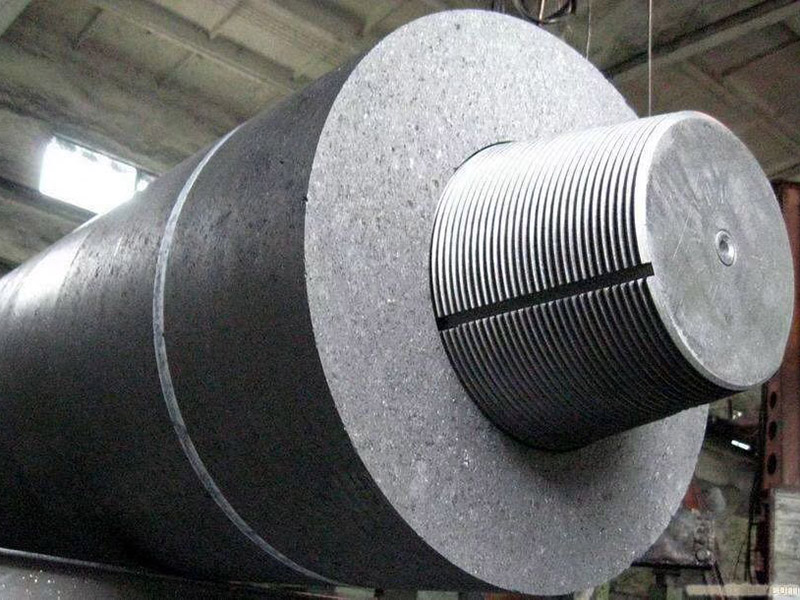

The electrodes carry the electricity that heats electric arc furnaces, the vast majority steel furnaces. They are made from petroleum coke after it is mixed with petroleum pitch, extruded and shaped, then baked to sinter it, and then graphitized by heating it above the temperature (3000 °C) that converts carbon to graphite. They can vary in size up to 11 ft. long and 30 in. in diameter.

Usage

-

01

An increasing proportion of global steel is made using electric arc furnaces -

02

The electric arc furnace itself is getting more efficient and making more steel per tonne of electrode

Typical properties of UHP graphite electrodes

|

Applicable Furmace Dia |

AC Furnace |

DC Furnace |

|||

|

300-400mm |

450-500mm |

550-600mm |

650-700mm |

||

|

Bulk Density |

g/cm³ |

1.65~1.76 |

1.64~1.75 |

1.64~1.75 |

1.64~1.75 |

|

Specific Resistance |

μΩM |

4.2~6.0 |

4.2~6.0 |

4.2~6.0 |

4.2~5.5 |

|

Elastic Modulus |

Gpa |

7~14 |

7~14 |

7~14 |

7~14 |

|

kgf/mm² |

700~1,400 |

700~1,400 |

700~1,400 |

700~1,400 |

|

|

Flexural Strength |

MPa |

10.5~15 |

10~15 |

10~15 |

10~15 |

|

kgf/cm² |

105~150 |

100〜150 |

100-150 |

100~150 |

|

|

N/cm² |

1,050~1,500 |

1,000~1,500 |

1,000~1,500 |

1,000~1,500 |

|

|

Coefficient Of Thermal |

X10~-6/℃ |

1.0~1.5 |

1.0~1.5 |

1.0~1.5 |

1.0~1.4 |

|

Real Density |

g/cm³ |

2.20~2.23 |

2.20~2.23 |

2.20~2.23 |

2.20~2.23 |

|

Porosity |

% |

20~26 |

20~27 |

20~27 |

20~27 |

|

Ash Content |

% |

≤0.2 |

≤0.2 |

≤0.2 |

≤0.2 |

Typical properties of nipples

| Specifications |

≤φ400 |

φ450-500 |

φ550 |

φ600-700 |

| Specific Resistance (μΩM ) |

≤4.0 |

≤3.8 |

≤3.6 |

≤3.6 |

| Flexural Strength (MPa) |

18-24 |

17-25 |

20-28 |

20-28 |

| astic Modulus (GPa) |

≤18 |

≤18 |

≤18 |

≤18 |

| Bulk Density (g/cm³) |

1.76-1.84 |

1.78-1.84 |

1.79-1.86 |

1.79-1.86 |

| Coefficient Of Thermal Expansion (106/℃) |

0.9-1.3 |

0.9-1.2 |

0.9-1.1 |

0.9-1.1 |

| Ash Content (%) |

≤0.3 |

≤0.3 |

≤0.3 |

≤0.3 |

Current carrying capacity for UHP graphite electrodes

| Current Capacity Of UHP Graphite Electrodes | |||||

| Specifications | Current Capacity(A) | Current Density(A/cm²) | |||

| (inch) | (mm) | AC | DC | AC | DC |

| 12 | 300 | 18,000-32,000 | - | 24-43 | - |

| 14 | 350 | 22,000-39,000 | - | 22-39 | - |

| 16 | 400 | 28,000-47,000 | - | 21-36 | - |

| 18 | 450 | 34,000-55,000 | - | 21-33 | - |

| 20 | 500 | 41,000-63,000 | - | 20-31 | - |

| 22 | 550 | 48,000-70,000 | 65,000-78,000 | 19-28 | 26-32 |

| 24 | 600 | 55,000-80,000 | 75,000-90,000 | 19-27 | 26-31 |

| W | 650 | 69,000-89,000 | 87,000-104,000 | 20-26 | 25-30 |

| 28 | 700 | 80,000-100,000 | 100,000-120,000 | 20-25 | 25-30 |

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. High-quality is our life. Consumer need to have is our God for High definition Graphite Electrode In Furnace - UHP Grades Graphite Electrodes – Sungraf , The product will supply to all over the world, such as: United Arab emirates, Guyana, Zurich, Our company has built stable business relationships with many well-known domestic companies as well as oversea customers. With the goal of providing high quality products to customers at low cots, we are committed to improving its capacities in research, development, manufacturing and management. We have honored to receive recognition from our customers. Till now we have passed ISO9001 in 2005 and ISO/TS16949 in 2008. Enterprises of quality of survival, the credibility of development for the purpose, sincerely welcome domestic and foreign businessmen to visit to discuss cooperation.

We are old friends, the company's product quality has been always very good and this time the price is also very cheap.