Hot-selling Graphite In Making Electrodes - UHP Grades Graphite Electrodes – Sungraf Detail:

Products Details

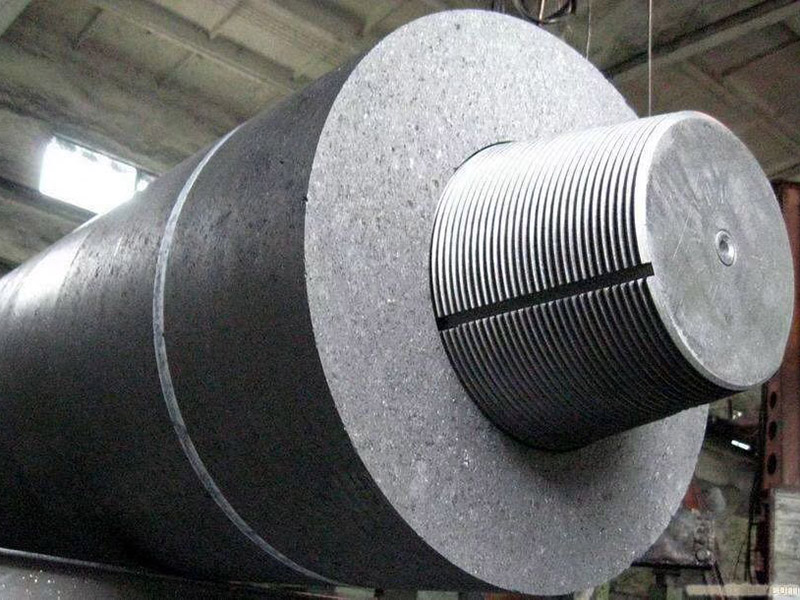

The electrodes carry the electricity that heats electric arc furnaces, the vast majority steel furnaces. They are made from petroleum coke after it is mixed with petroleum pitch, extruded and shaped, then baked to sinter it, and then graphitized by heating it above the temperature (3000 °C) that converts carbon to graphite. They can vary in size up to 11 ft. long and 30 in. in diameter.

Usage

-

01

An increasing proportion of global steel is made using electric arc furnaces -

02

The electric arc furnace itself is getting more efficient and making more steel per tonne of electrode

Typical properties of UHP graphite electrodes

|

Applicable Furmace Dia |

AC Furnace |

DC Furnace |

|||

|

300-400mm |

450-500mm |

550-600mm |

650-700mm |

||

|

Bulk Density |

g/cm³ |

1.65~1.76 |

1.64~1.75 |

1.64~1.75 |

1.64~1.75 |

|

Specific Resistance |

μΩM |

4.2~6.0 |

4.2~6.0 |

4.2~6.0 |

4.2~5.5 |

|

Elastic Modulus |

Gpa |

7~14 |

7~14 |

7~14 |

7~14 |

|

kgf/mm² |

700~1,400 |

700~1,400 |

700~1,400 |

700~1,400 |

|

|

Flexural Strength |

MPa |

10.5~15 |

10~15 |

10~15 |

10~15 |

|

kgf/cm² |

105~150 |

100〜150 |

100-150 |

100~150 |

|

|

N/cm² |

1,050~1,500 |

1,000~1,500 |

1,000~1,500 |

1,000~1,500 |

|

|

Coefficient Of Thermal |

X10~-6/℃ |

1.0~1.5 |

1.0~1.5 |

1.0~1.5 |

1.0~1.4 |

|

Real Density |

g/cm³ |

2.20~2.23 |

2.20~2.23 |

2.20~2.23 |

2.20~2.23 |

|

Porosity |

% |

20~26 |

20~27 |

20~27 |

20~27 |

|

Ash Content |

% |

≤0.2 |

≤0.2 |

≤0.2 |

≤0.2 |

Typical properties of nipples

| Specifications |

≤φ400 |

φ450-500 |

φ550 |

φ600-700 |

| Specific Resistance (μΩM ) |

≤4.0 |

≤3.8 |

≤3.6 |

≤3.6 |

| Flexural Strength (MPa) |

18-24 |

17-25 |

20-28 |

20-28 |

| astic Modulus (GPa) |

≤18 |

≤18 |

≤18 |

≤18 |

| Bulk Density (g/cm³) |

1.76-1.84 |

1.78-1.84 |

1.79-1.86 |

1.79-1.86 |

| Coefficient Of Thermal Expansion (106/℃) |

0.9-1.3 |

0.9-1.2 |

0.9-1.1 |

0.9-1.1 |

| Ash Content (%) |

≤0.3 |

≤0.3 |

≤0.3 |

≤0.3 |

Current carrying capacity for UHP graphite electrodes

| Current Capacity Of UHP Graphite Electrodes | |||||

| Specifications | Current Capacity(A) | Current Density(A/cm²) | |||

| (inch) | (mm) | AC | DC | AC | DC |

| 12 | 300 | 18,000-32,000 | - | 24-43 | - |

| 14 | 350 | 22,000-39,000 | - | 22-39 | - |

| 16 | 400 | 28,000-47,000 | - | 21-36 | - |

| 18 | 450 | 34,000-55,000 | - | 21-33 | - |

| 20 | 500 | 41,000-63,000 | - | 20-31 | - |

| 22 | 550 | 48,000-70,000 | 65,000-78,000 | 19-28 | 26-32 |

| 24 | 600 | 55,000-80,000 | 75,000-90,000 | 19-27 | 26-31 |

| W | 650 | 69,000-89,000 | 87,000-104,000 | 20-26 | 25-30 |

| 28 | 700 | 80,000-100,000 | 100,000-120,000 | 20-25 | 25-30 |

Product detail pictures:

Related Product Guide:

We constantly continually give you essentially conscientious client provider, plus the widest variety of designs and styles with high quality materials. These initiatives include the availability of customized designs with speed and dispatch for Hot-selling Graphite In Making Electrodes - UHP Grades Graphite Electrodes – Sungraf , The product will supply to all over the world, such as: Finland, Oman, UK, Now the competition in this field is very fierce; but we will still offer high quality, reasonable price and considerate service in an endeavor to achieve win-win goal. Change for the better! is our slogan, which means A better world is before us, so let's enjoy it! Change for the better! Are you ready?

It is really lucky to meet such a good supplier, this is our satisfied cooperation, I think we will work again!