OEM Factory for Graphite Electrode For Ladle Furnace - UHP Grades Graphite Electrodes – Sungraf Detail:

Products Details

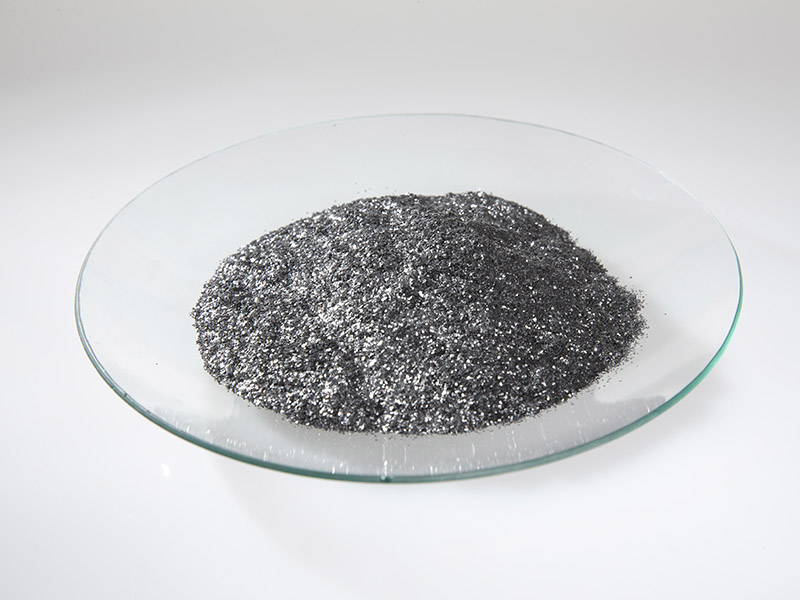

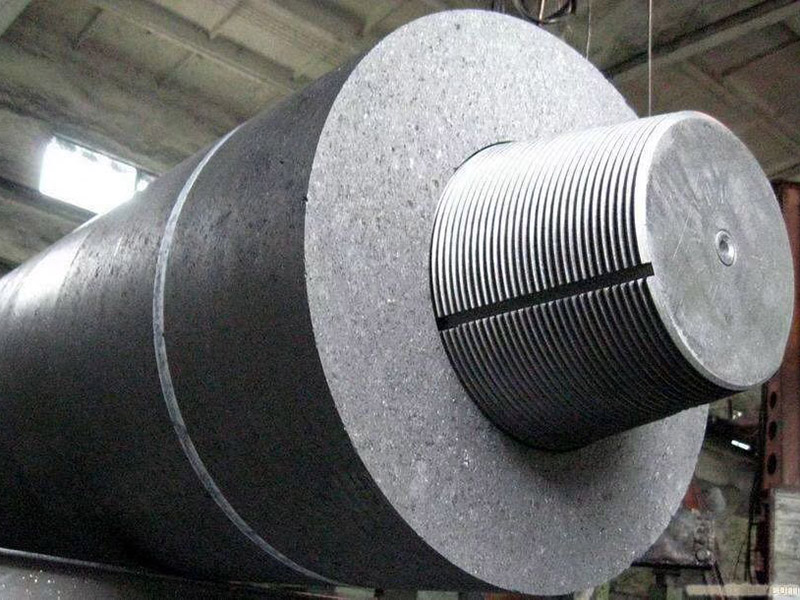

The electrodes carry the electricity that heats electric arc furnaces, the vast majority steel furnaces. They are made from petroleum coke after it is mixed with petroleum pitch, extruded and shaped, then baked to sinter it, and then graphitized by heating it above the temperature (3000 °C) that converts carbon to graphite. They can vary in size up to 11 ft. long and 30 in. in diameter.

Usage

-

01

An increasing proportion of global steel is made using electric arc furnaces -

02

The electric arc furnace itself is getting more efficient and making more steel per tonne of electrode

Typical properties of UHP graphite electrodes

|

Applicable Furmace Dia |

AC Furnace |

DC Furnace |

|||

|

300-400mm |

450-500mm |

550-600mm |

650-700mm |

||

|

Bulk Density |

g/cm³ |

1.65~1.76 |

1.64~1.75 |

1.64~1.75 |

1.64~1.75 |

|

Specific Resistance |

μΩM |

4.2~6.0 |

4.2~6.0 |

4.2~6.0 |

4.2~5.5 |

|

Elastic Modulus |

Gpa |

7~14 |

7~14 |

7~14 |

7~14 |

|

kgf/mm² |

700~1,400 |

700~1,400 |

700~1,400 |

700~1,400 |

|

|

Flexural Strength |

MPa |

10.5~15 |

10~15 |

10~15 |

10~15 |

|

kgf/cm² |

105~150 |

100〜150 |

100-150 |

100~150 |

|

|

N/cm² |

1,050~1,500 |

1,000~1,500 |

1,000~1,500 |

1,000~1,500 |

|

|

Coefficient Of Thermal |

X10~-6/℃ |

1.0~1.5 |

1.0~1.5 |

1.0~1.5 |

1.0~1.4 |

|

Real Density |

g/cm³ |

2.20~2.23 |

2.20~2.23 |

2.20~2.23 |

2.20~2.23 |

|

Porosity |

% |

20~26 |

20~27 |

20~27 |

20~27 |

|

Ash Content |

% |

≤0.2 |

≤0.2 |

≤0.2 |

≤0.2 |

Typical properties of nipples

| Specifications |

≤φ400 |

φ450-500 |

φ550 |

φ600-700 |

| Specific Resistance (μΩM ) |

≤4.0 |

≤3.8 |

≤3.6 |

≤3.6 |

| Flexural Strength (MPa) |

18-24 |

17-25 |

20-28 |

20-28 |

| astic Modulus (GPa) |

≤18 |

≤18 |

≤18 |

≤18 |

| Bulk Density (g/cm³) |

1.76-1.84 |

1.78-1.84 |

1.79-1.86 |

1.79-1.86 |

| Coefficient Of Thermal Expansion (106/℃) |

0.9-1.3 |

0.9-1.2 |

0.9-1.1 |

0.9-1.1 |

| Ash Content (%) |

≤0.3 |

≤0.3 |

≤0.3 |

≤0.3 |

Current carrying capacity for UHP graphite electrodes

| Current Capacity Of UHP Graphite Electrodes | |||||

| Specifications | Current Capacity(A) | Current Density(A/cm²) | |||

| (inch) | (mm) | AC | DC | AC | DC |

| 12 | 300 | 18,000-32,000 | - | 24-43 | - |

| 14 | 350 | 22,000-39,000 | - | 22-39 | - |

| 16 | 400 | 28,000-47,000 | - | 21-36 | - |

| 18 | 450 | 34,000-55,000 | - | 21-33 | - |

| 20 | 500 | 41,000-63,000 | - | 20-31 | - |

| 22 | 550 | 48,000-70,000 | 65,000-78,000 | 19-28 | 26-32 |

| 24 | 600 | 55,000-80,000 | 75,000-90,000 | 19-27 | 26-31 |

| W | 650 | 69,000-89,000 | 87,000-104,000 | 20-26 | 25-30 |

| 28 | 700 | 80,000-100,000 | 100,000-120,000 | 20-25 | 25-30 |

Product detail pictures:

Related Product Guide:

Our personnel are always inside the spirit of continuous improvement and excellence, and together with the outstanding excellent goods, favorable price and good after-sales services, we try to gain every customer's trust for OEM Factory for Graphite Electrode For Ladle Furnace - UHP Grades Graphite Electrodes – Sungraf , The product will supply to all over the world, such as: Lithuania, Benin, Myanmar, We are your reliable partner in the international markets of our products. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade products in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad, to create a great future. Welcome to Visit our factory. Looking forward to have win-win cooperation with you.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.